Innovation Tech has partnered with CALDAN Conveyor to provide conveyor solutions to our customer in the coating business who benefits from CALDAN creative design expertise and their well-constructed, modular conveyor components as well as Innovation Tech system integration expertise and local support in the USA.

Floor Conveyors

Our chain-based floor conveyor systems come as powered single line (monorail), fixed pitch or Power & Free wagon-based conveyance that can handle weights up to 2,000 kg. All the systems have been developed for the extremes of the surface finishing industry and are designed for high accuracy of presentation of product to process along with excellent stability characteristics.

Why chose floor conveyor:

- Accurate product presentation to the process

- Easy loading of products and fixture exchange

- Easy installation, commissioning, and maintenance with components at floor level

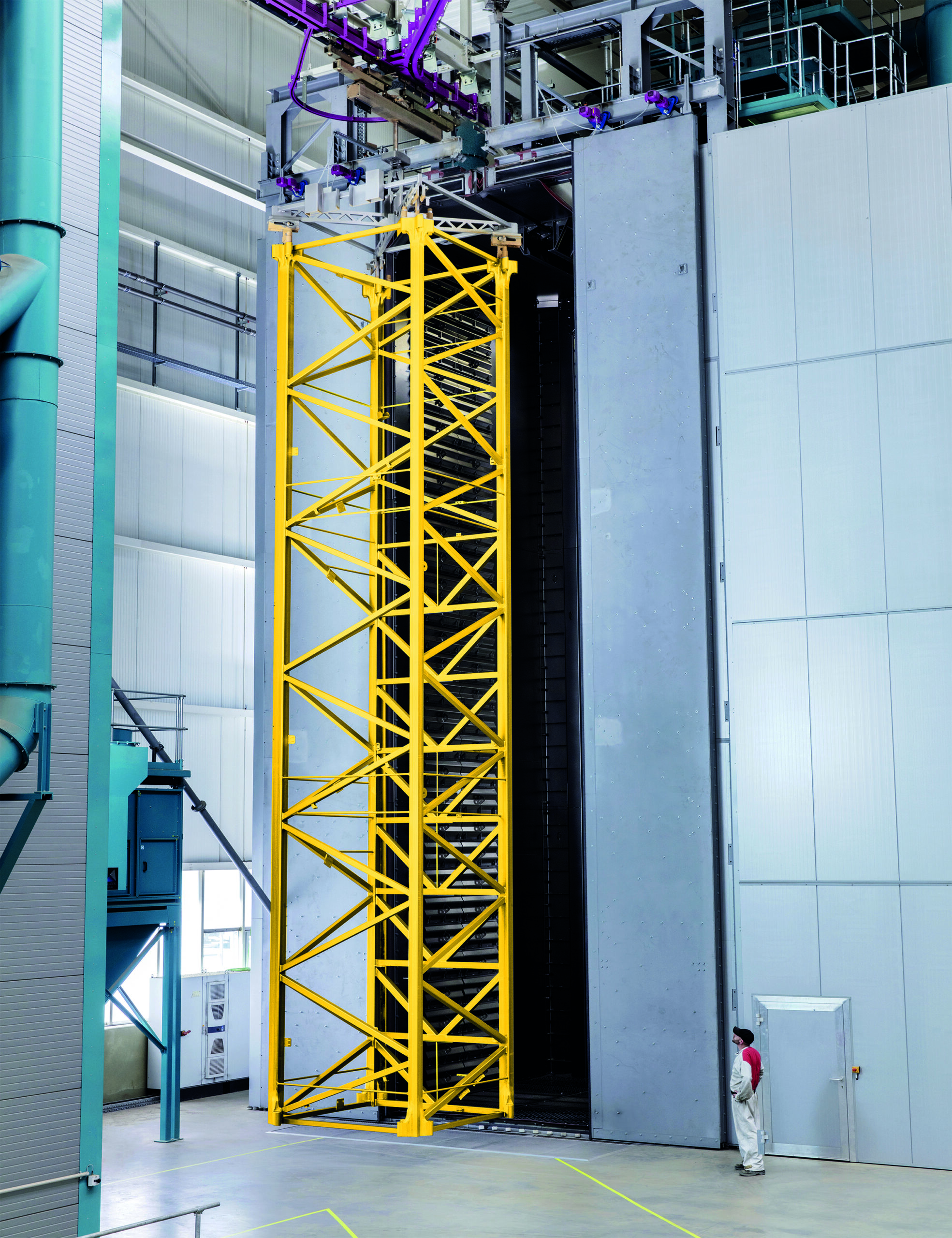

Overhead Conveyor

Our overhead conveyor systems range from simple manual systems, through powered single line (monorail) to complex Power & Free systems that can handle weights up to 22,000 lbs. They are all developed first and foremost for the extremes of the surface finishing industry and are designed for operating at high efficiencies with minimum maintenance.

Why chose overhead conveyor:

- Take advantage of the generally unused vertical space above the work area.

- The conveyor is above the process and away from over-spray, powder dust, and water/chemical drip in wet environment.

- Large parts hung on load bar.

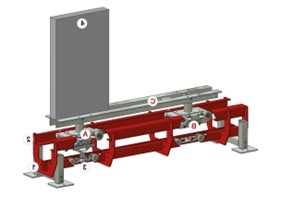

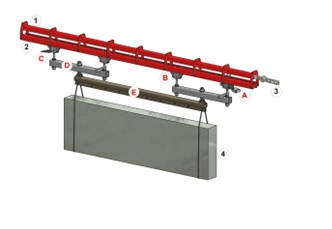

Shuttle System

The shuttle systems are designed for cross- and lengthwise transportation of various items, mainly used in partially automated surface treatment areas or in assembly areas. Due to their ability to perform very space-saving transportation, the systems are primarily used to handle heavy or bulky goods.

Why chose shuttle system:

- Possibility of performing directional changes.

- Can be used as very cost-effective static buffers.

- Space-saving for long bulky goods.

Monorail

The single line or monorail conveyor is a simple and reliable system where wagons or hangers are attached to a chain with a fixed pitch. The chain is running inside an open track profile and pulled by the drive unit with a VFD controlled motor. The chain is stretched with a pneumatic tension unit.

Why chose single line / monorail conveyor:

- Simple and low-cost conveyance solution that requires minimum maintenance.

- Simple controls that require minimum user training.

Power & Free

The Power and Free conveyor, which is the most technically complex type, provides asynchronous conveying. Each set of trolleys / wagons can stop and start independently and move loads at different speeds.

Power & Free conveyors are based on a dual profile system. The upper profile is used for the ‘Power’ chain and the lower ‘Free’ profile is used for the trolleys. Pusher dogs are fitted to the power chain at the same pitch and are used to pull the carriers around the system.

Stop stations are used to disengage the link between the power chain and the trolleys. When a stop station is closed, the trolley stops while the power chain continues to move. The design of the pusher and trolley allows multiple wagons to accumulate behind a stop station.