Benefits of Machine Vision Systems:

- 2D and 3D positioning

- Rotation recognition of objects to guide robot and ensure process accuracy

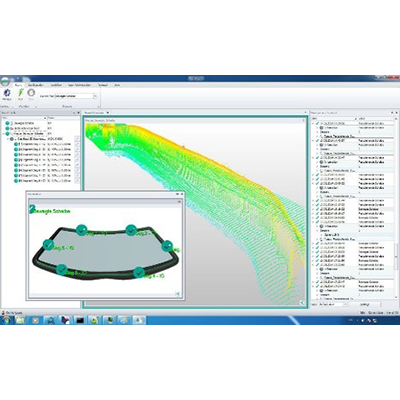

- In process quality inspection of parts for dimensional or surface defects

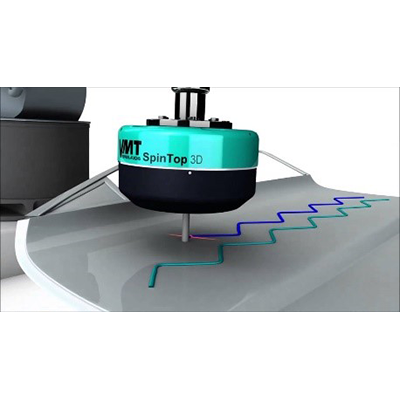

- In process bead size inspection to ensure proper seal

- Automation of manual tasks such as bin picking, not possible to do without sight

- Part recognition for automatic program selection to eliminate human errors

- Part sizing or 3D profile scanning for automatic path program generation in high product mix production

Core Competencies

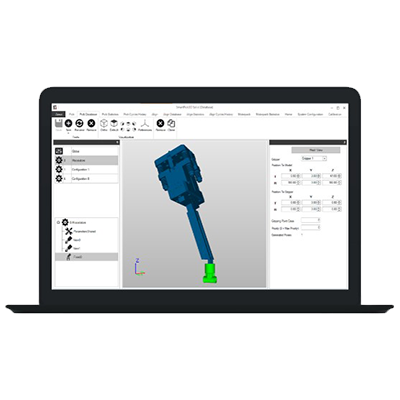

Our team has worked with 2D and 3D machine vision systems from any major vision system suppliers (Cognex, Keyance, VMT, ISRA etc) as well as random bin pick system from EyeT+. We have the experience to integrate single and multi camara systems for part location, part recognition, and part inspection with any of our partners robots.

Robot

Application

Vision SW

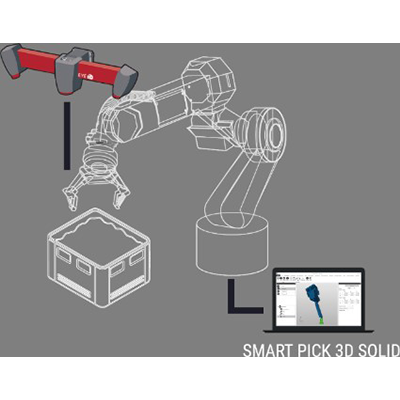

EyeT+ Random Bin Picking

Random bin picking systems combine machine vision and robotics to create a solution to pick and extract parts from a bin. EyeT+ is a CAD based bin picking solution that uses 3D CAD models of the parts to identify part geometry and position as well as 3D CAD of picking tool and bin to define picking strategy (how to pick part) and calculate optimal robot motion out of the bin without collision. The strength of EyeT+ CAD based system is the detailed part information for accurate pick and use of EyeT+ TWIN-PICK to simulate and evaluate the system’s ability to pick your part before buying a bin picking system.