POMA System GmbH designs and manufactures high-quality paint components (gear pumps, fluid valves, color changers, 2k mixers, and spray atomizers) for low pressure paint systems. POMA and Innovation Tech – North America distributor of POMA System GmbH products – work together to supply engineered paint supply and dosing solutions our NA customers.

Pig Systems – A paint saving homerun!

A pig system is a method to minimize paint waste and solvent usage during color change. In simplicity a ball or cylinder pig is used to push paint back into the supply system instead of flushing line content into the waste collection system. The ROI can quickly be calculated with information on paint line volume calculation (paint line ID and Length) and number of color changes per day/year. The ROI is often less than a year.

When loading, paint pushes a ball or cylinder pig from a pig launch block often located outside the paint booth to a pig catch block close to the spray applicator. When flushing, compressed air pushes the pig and paint back into the supply system. The pig is locked in the launch block, and a small amount of solvent will clean around the pig and the empty paint line out to the applicator.

Gear Pumps – Solution to paint quality issues

Accurate paint dosing is key to obtaining uniform paint thickness and consistent quality that will improve your throughput and bottom line. With gear pumps you can achieve accurate fluid flow within 2% of setpoint without consideration of viscosity and temperature fluctuation. In a two-component dosing system, the gear pump will provide accurate and homogeneous mixing of the epoxy/polyurethane paint.

Gear pumps are so-called positive fluid displacement devices where two meshed gear wheels push fluid through a precision machined housing. The sizing of the gear pump – 0.6cc / 1.2cc / 3cc / 6cc / 9cc – indicates how much fluid is pushed out per rotation. The gear pumps are driven by a motor, so the motor rpm determines actual flow rate (rpm x gear pump size)

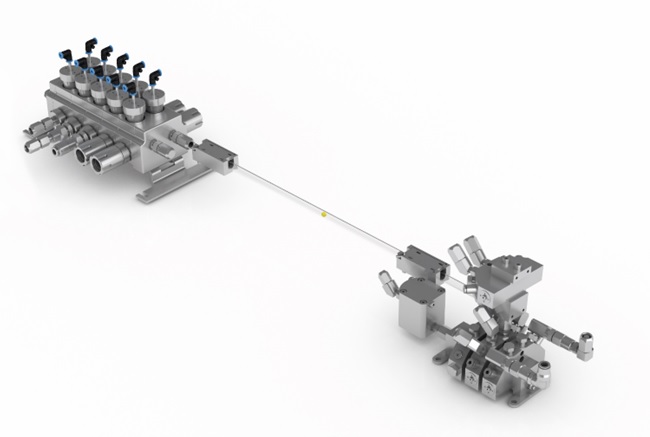

Supply and Dosing Systems

With our portfolio of POMA equipment, we can offer components and system for low pressure paint system such as:

- Paint supply components and system

- Mini supply systems

- Pig supply system circulation header system (cylinder pig)

- Pig AB color change system (ball pig) simplified pig system

- Paint dosing components and system

- Gear pumps

- Fluid regulators

- Fluid valves and blocks

- 2K mixer blocks

- Spray guns

- Voltage separation system