Benefits of Collaborative Robots:

- Safe and collaborative by design

- Hand guided motion and path programming

- Easy, intuitive setup and programming interface

- Lightweight and space-saving robots that run on a standard 12O VAC outlet.

- Huge ecosystem of End-of-Arm-Tools (EOAT) and auxiliary equipment for various applications

- Easy and fast deployment with pre-engineered application packages

- Great for simple applications like machine tending, inspection, pick-n-place, dispensing and polishing

Core Competencies

Our team has to the knowledge evaluate your process, provide a documented risk assessment and design a truly collaborative robot system. We will work with you and your team to select the right collaborative robot with tooling for your application and ensure proper integration into your production.

Robot

Tooling

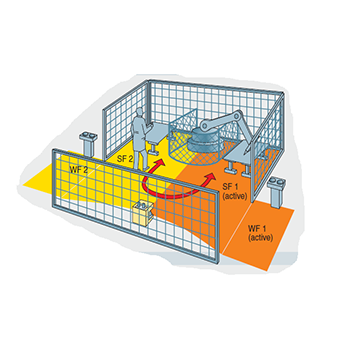

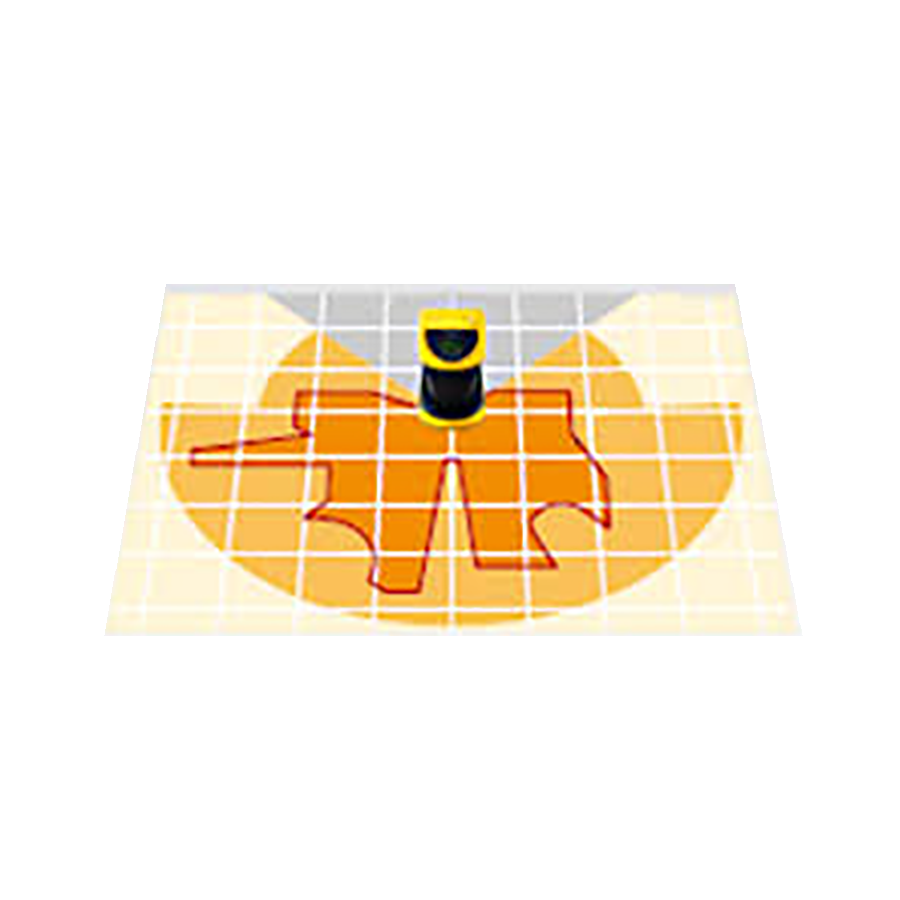

Safety

FANUC CRX-10ia-L robot with OnRobot RG2 finger gripper

Fanuc CRX-10ia-L robot is a part of Fanuc’s extensive line of collaborative robots. The lightweight robot runs on standard 120 VAC and is easy to commission and install. Equipped with the OnRobot RG2 electrical force sensing finger gripper, the robot can pick parts with variable width and sense the gripping force including lost part detection. This solution is ideal for machine tending and pick-n-place applications.

OnRobot EOAT Ecosystem

Description to come.

ABB GOFA Robot with OnRobot 2FG7 Parallel Gripper

ABB GoFa robot is a part of ABBs lineup of single or dual arm collaborative robots. The lightweight robot runs on standard 120 VAC and is easy to commission and install. Equipped with the IP 67 OnRobot 2FG7 electrical parallel gripper, the robot can used for inside or outside pick of parts in tight places. Solutions is ideal for machine tending and pick-n-place applications.